According to iso 14644 1 a cleanroom is a room in which the concentration of airborne particles is controlled and which is constructed and used in a manner to minimize the introduction generation and retention of particles inside the room and in which other relevant parameters e g.

Iso 1 clean room uses.

The room eliminates sub micron airborne contamination generated from people processes facilities and equipment.

In the uk british standard 5295 is used to classify cleanrooms.

This method is simple.

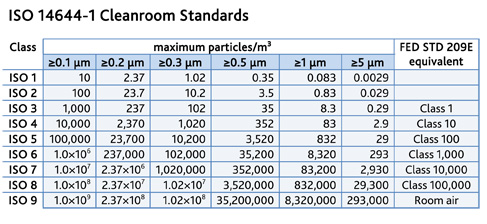

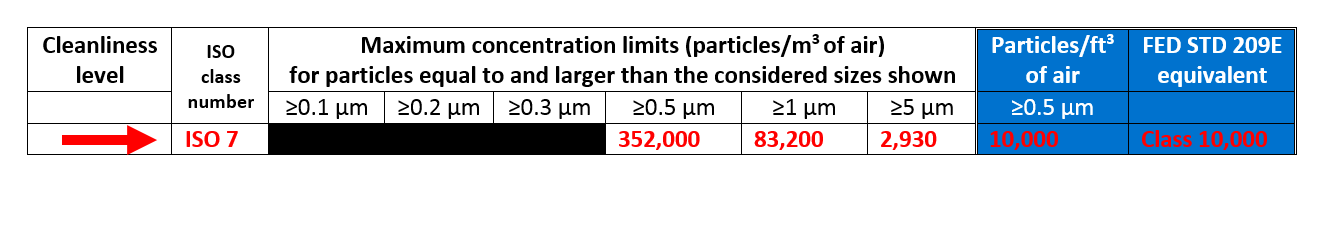

To meet requirements of a clean room as defined by federal standard 209e and newer iso standards all clean rooms must not exceed a particulate count as specified in the air cleanliness class.

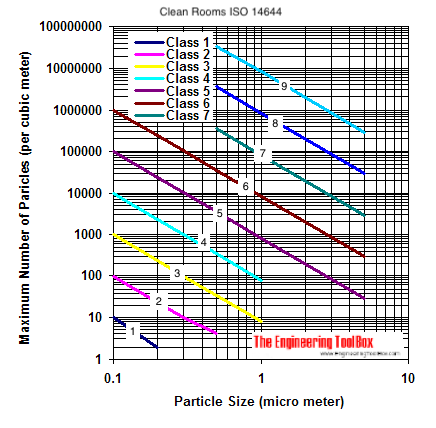

The lower the iso class rating the cleaner the environment.

No assumptions are made regarding the distribution of the actual particle counts over the area of the cleanroom or clean zone.

The cleanroom classification standards fs 209e and iso 14644 1 require specific particle count measurements and calculations to classify the cleanliness level of a cleanroom or clean area.

Iso class 1 the cleanest cleanroom is iso 1 used in industries such as life sciences and electronics that require nanotechnology or ultra fine particulate processing.

The number assigned to the class is the.

The recommended air changes per hour for an iso class 1 clean room is 500 750 and the ceiling coverage should be 80 100.

Ordinary room air is around class 1 000 000 or iso 9.

A cleanroom must have less than 35 200 000 particles 0 5 micron per cubic meter and 20 hepa filtered air changes per hour.

There are nine iso classes.

While in iso 14644 1 1999 an underlying assumption was that the particle counts follow the same normal distribution across the room this assumption has now been discarded to allow the sampling to be used in rooms where.

By comparison a typical office space would be 5 10 times more dirty.

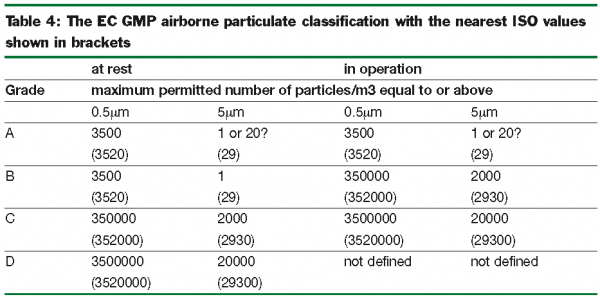

Iso 14644 1 and iso 14698.

As of november 29th 2001 the federal standard 209e has been replaced with iso 14644 1.

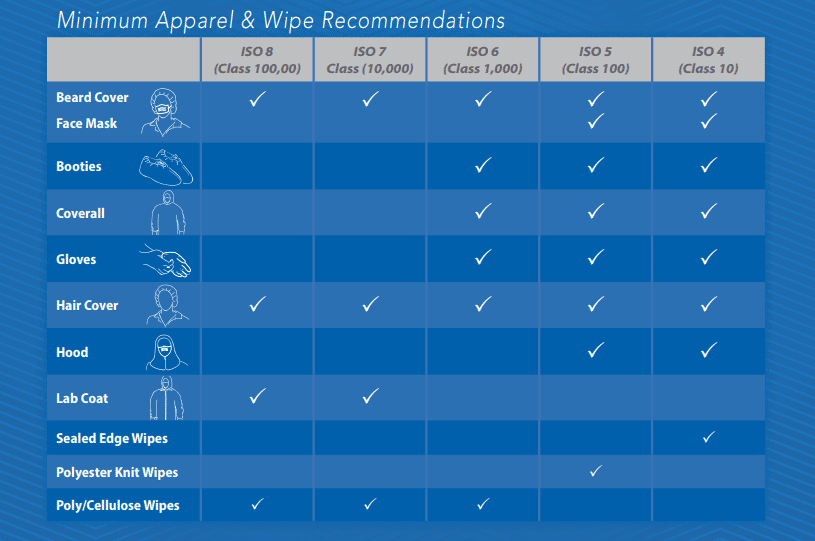

Iso 6 cleanroom class 1 000 in theory for an entire room to reach iso 6 air cleanliness you need to enter the cleanroom via an iso 8 ante room then go through an iso 7 to finally get into the iso 6 as shown in the image.

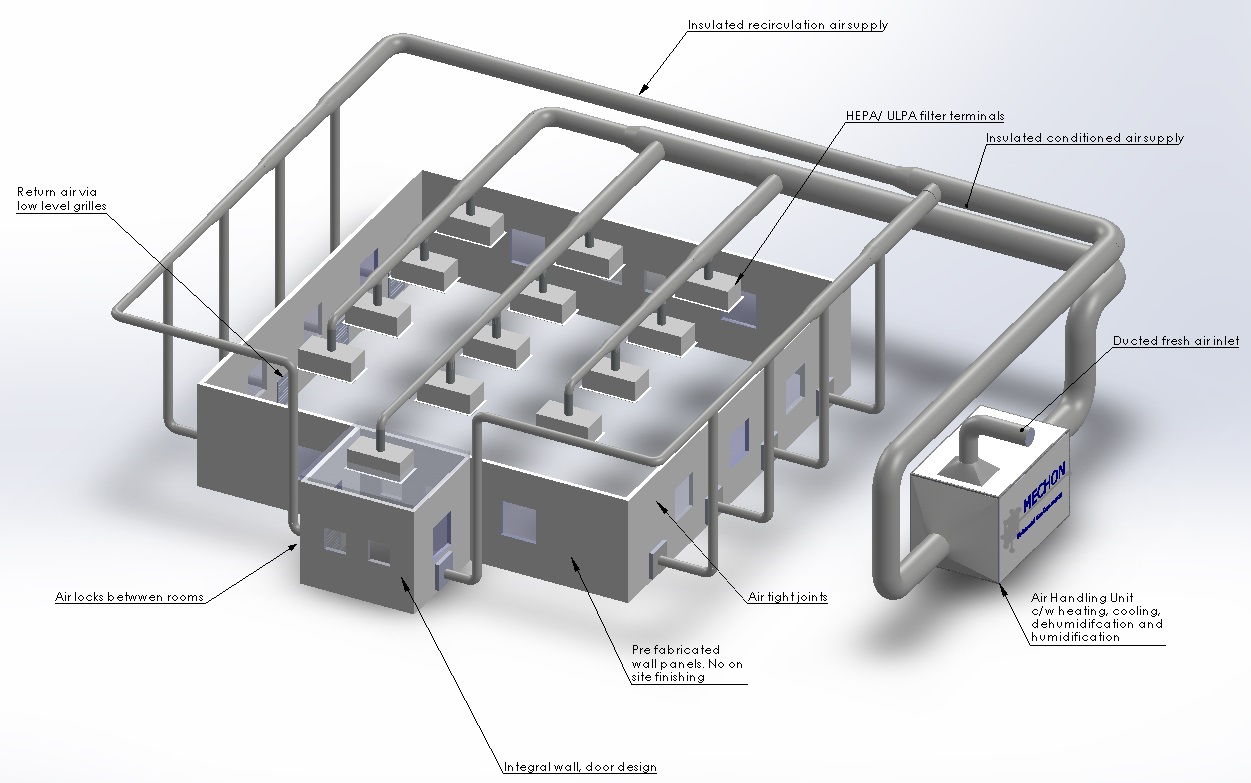

In positive pressure clean rooms air is constantly flowing out of the room.

The latter to cleanrooms where biocontamination may be an issue.

Iso 14644 1 clause 2 1 1 a cleanroom is a controlled environment where products are packed manufactured and assembled.

Negative pressure cleanrooms function exactly.

Iso 14644 1 and iso 14698 are non governmental standards developed by the international organization for standardization iso.

In reality however you can reach an iso 6 clean room with 1 recommendation is 2 airlock.

Temperature humidity and pressure are controlled as necessary.

Class 1 the cleanest to class 9.