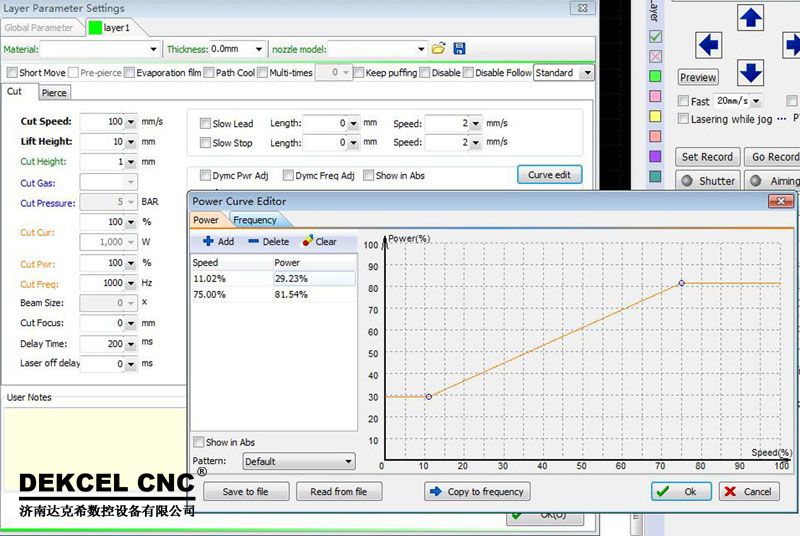

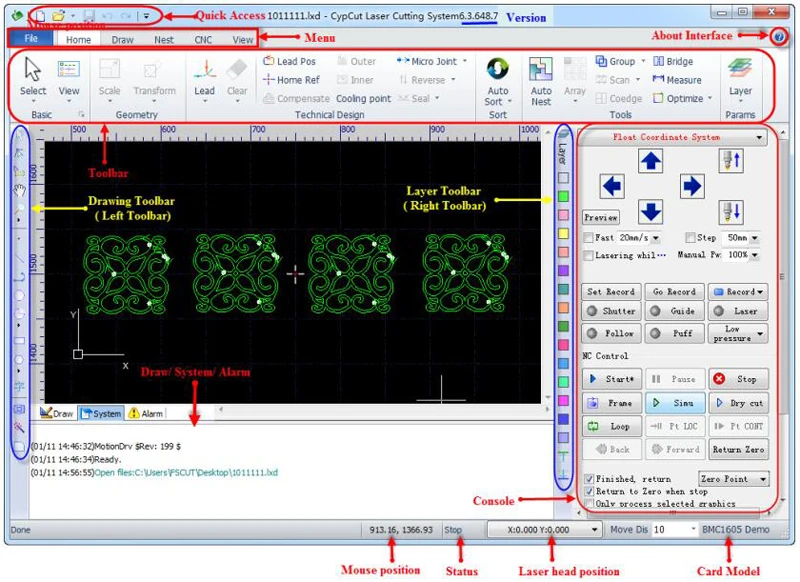

Cypcut laser cutting control system in short cypcut is a set of system software intended for flat laser cutting including laser cutting common function of setting and laser processing control.

Cypcut fiber laser cutting parameters.

High speed transmission higer cutting accuracy.

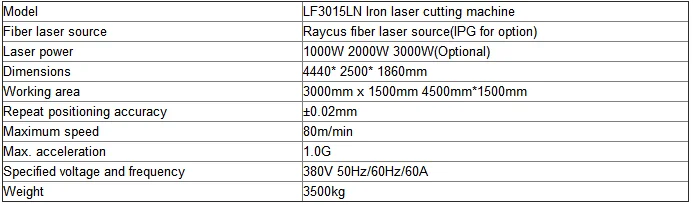

Machine technical parameters machine model jq.

Cooling system cw 6100 water chiller could well protect the laser device.

The color of each layer is unique which is convenient for browsing and configuring cutting graphics parameters.

The color of each layer is unique which is convenient for browsing and configuring cutting graphics parameters.

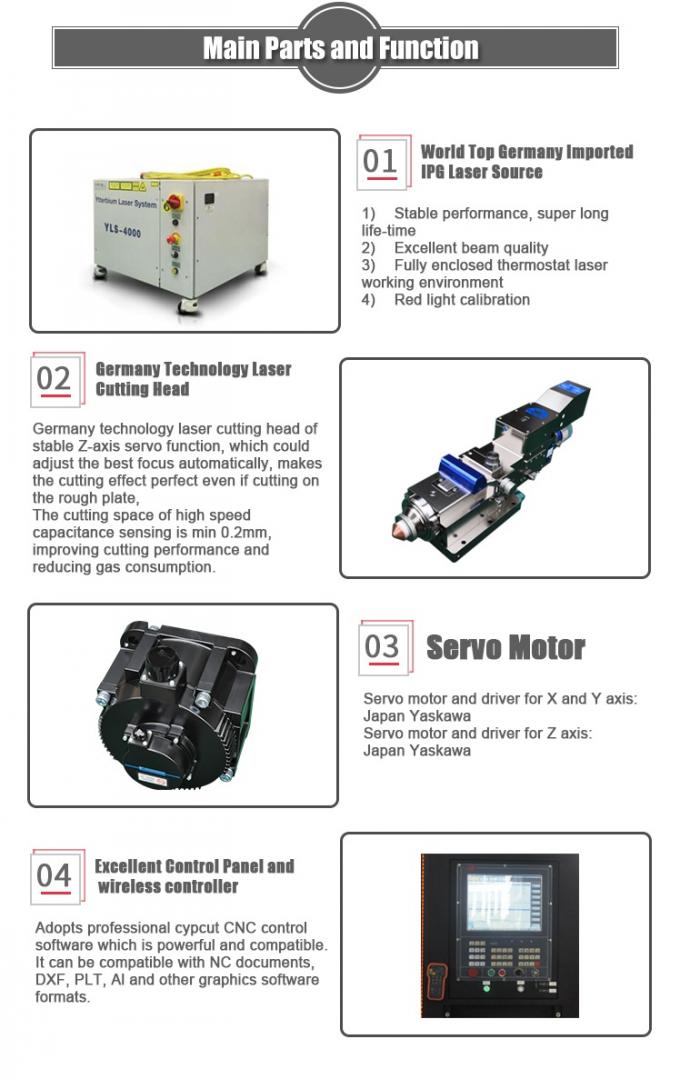

Professional cad cam automatic programming software and automatic nesting software support both chinese and english interface rich process parameters to maximize the savings of raw materials.

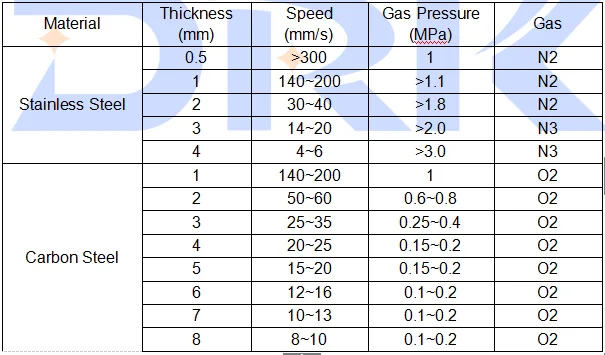

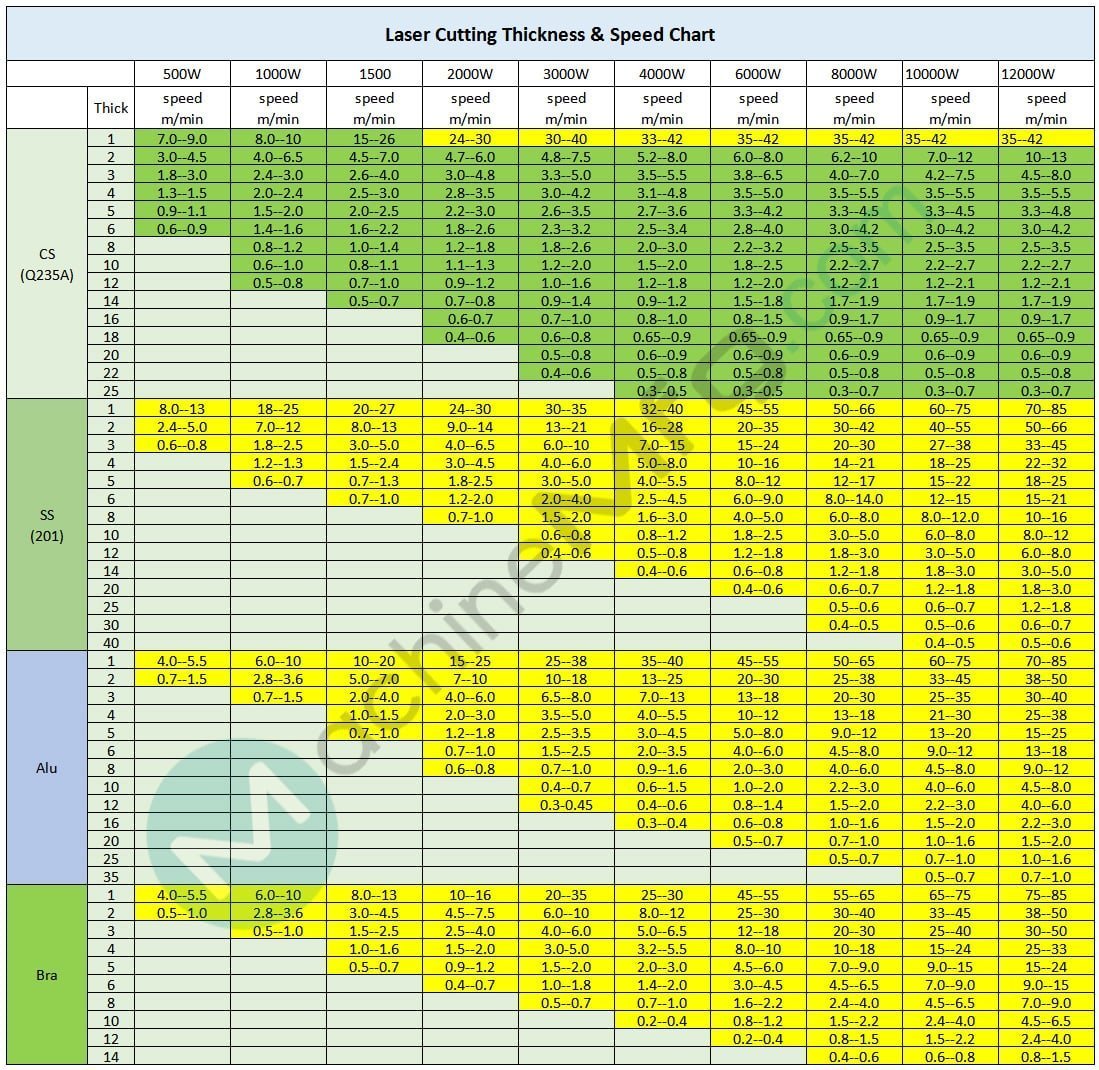

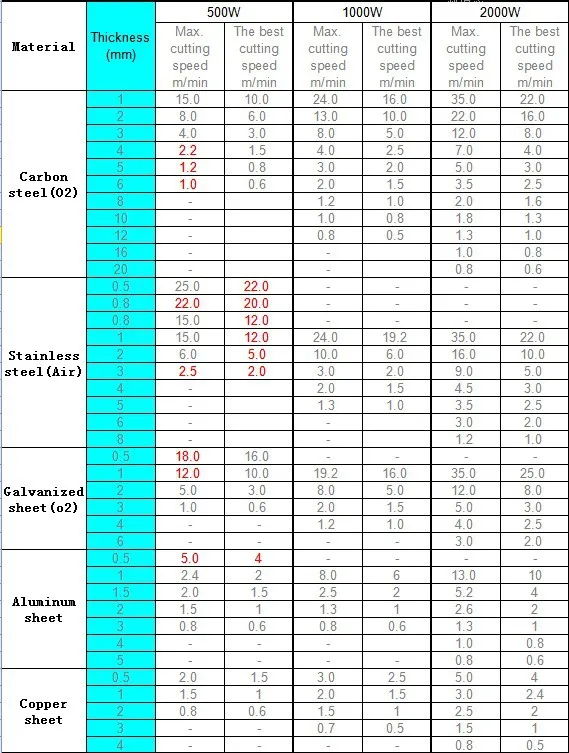

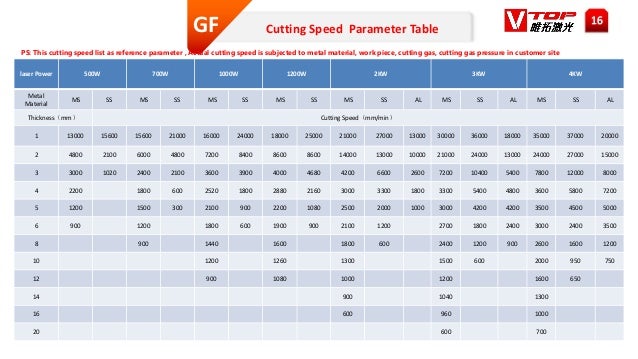

Cypcut provides 16 layers and each layer can be individually set including cutting speed laser power air pressure cutting height and other process parameters.

Morn professional tube fiber laser cutting machine integrates cnc technology laser cutting and precision machinery to carry out various graphic cutting on pipe fittings and profiles.

Most of its functions are used for processing the graphics parameters setting non standard edition of cutting process simulation and cutting.

3000 1500mm optional processing area.

Our fiber laser cutting machine has an automatic gear lubrication system.

Most of its functions are used for processing the graphics parameters setting non standard edition of cutting process simulation and cutting.

Cypcut laser cutting control system in short cypcut is a set of system software intended for flat laser cutting including laser cutting common function of setting and laser processing control.

Cypcut fscut2000 control system.

Cypcut provides 16 layers and each layer can be individually set including cutting speed laser power air pressure cutting height and other process parameters.

Laser head cypcut laser head with auto sensor which could adjust focal distance automatically.

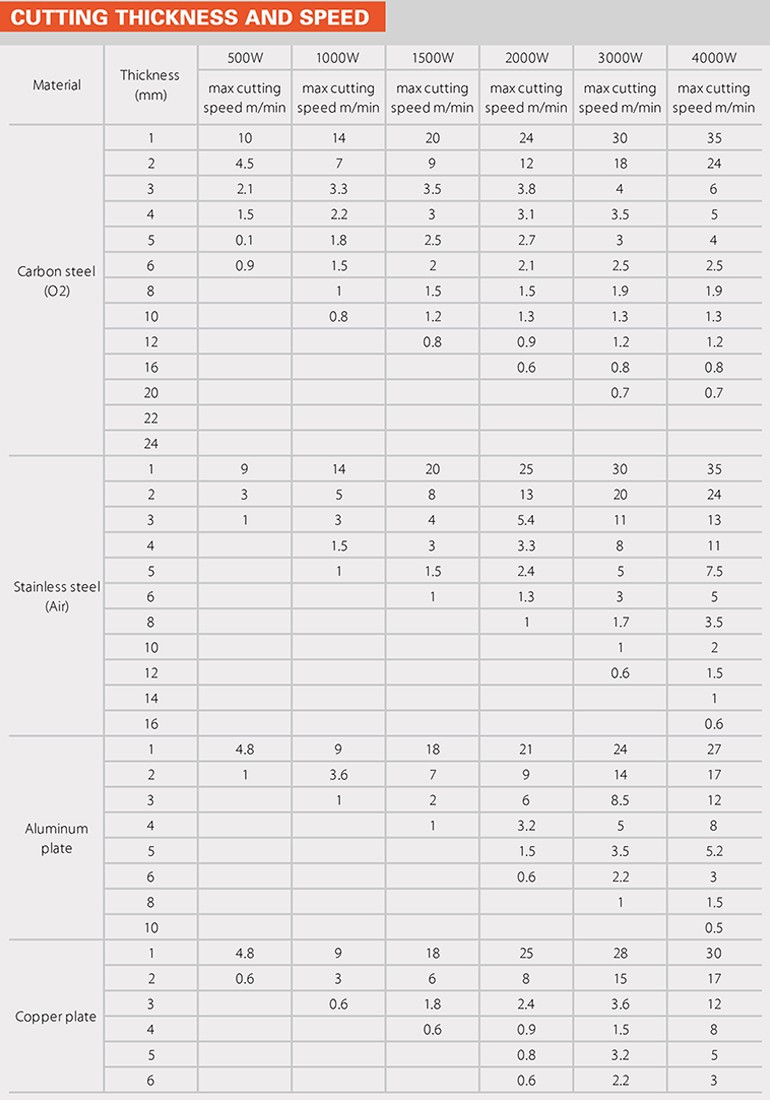

It provides high cutting precision smooth cut fast cutting speed and small kerf width and produces high quality more consistent parts especially beneficial.